No. 1442 vm Bottling & Packaging Assets Auckland all items s

Bottling & Packaging Assets… (Limited Time Only) All items SOLD

On behalf of Villa Maria Estate Ltd we are pleased to offer for sale

a substantial bottling/packaging line.

*Additional photos now available, go to IBL For Sale ref No.1441. https://www.ibl.co.nz/forsale.php?gr=1441

- Site location: Mangere, Auckland, New Zealand.

- The line is in service and fully operational, 8000bph 750ml.

- Sales negotiations will commence Monday 27th May 2024.

- Inspections and viewing will close 28th June 2024.

- Decommissioning commences 1st July 2024.

- Inspections are strictly by arrangement only, contact IBL 0274 442 944

- All offers are welcome, please direct to IBL ed@ibl.co.nz

- Site engineers are available for commentary.

Contact Exclusive Agents

- Industrial Brokers Ltd

- Ed O’Donnell (Managing Director)

- Cell 0274 442 944

- +64 274 442 944

- Email ed@ibl.co.nz

Terms and Conditions:

- Plant and Equipment is offered on an “as is, where is” basis.

- No warranties or guarantees are offered.

- Certificates/documentation available where/if possible.

- Sale and Purchase Agreement applies.

- Highest or any offer will not necessarily be accepted.

- Freight & Packing is the Purchaser's concern.

- Site visits PPE: as instructed (high vis, glasses, acceptable footwear...)

Brief Inventory

| ID | Qty | Description | . |

| 1 | 1x | De Palletizer | |

| 2 | 1x | De Elevator | |

| 3 | 1x | Inspection Camera | |

| 4 | 1x | Rinser | |

| 5 | 1x | Filler 54head 12500bph | |

| 6 | 1x | Screw Capper 12 head | |

| 8 | 1x | Laser coder | |

| 9 | 1x | Tap tone inspection | |

| 10 | 1x | Checkmat 1 | |

| 11 | 1x | Checkmat 2 | |

| 12 | 1x | Conveyors | |

| 13 | 1x | Conveyors | |

| 14 | 1x | Dyer | |

| 15 | 1x | Dehumidifier | |

| 17 | 1x | Label inspection camera | |

| 18 | 1x | Conveyors | |

| 19 | 1x | Packing table manual | |

| 20 | 2x | Tape machine | |

| 21 | 2x | Case Erectors | |

| 22 | 2x | Case printing device | |

| 23 | 1x | Carton conveyors | |

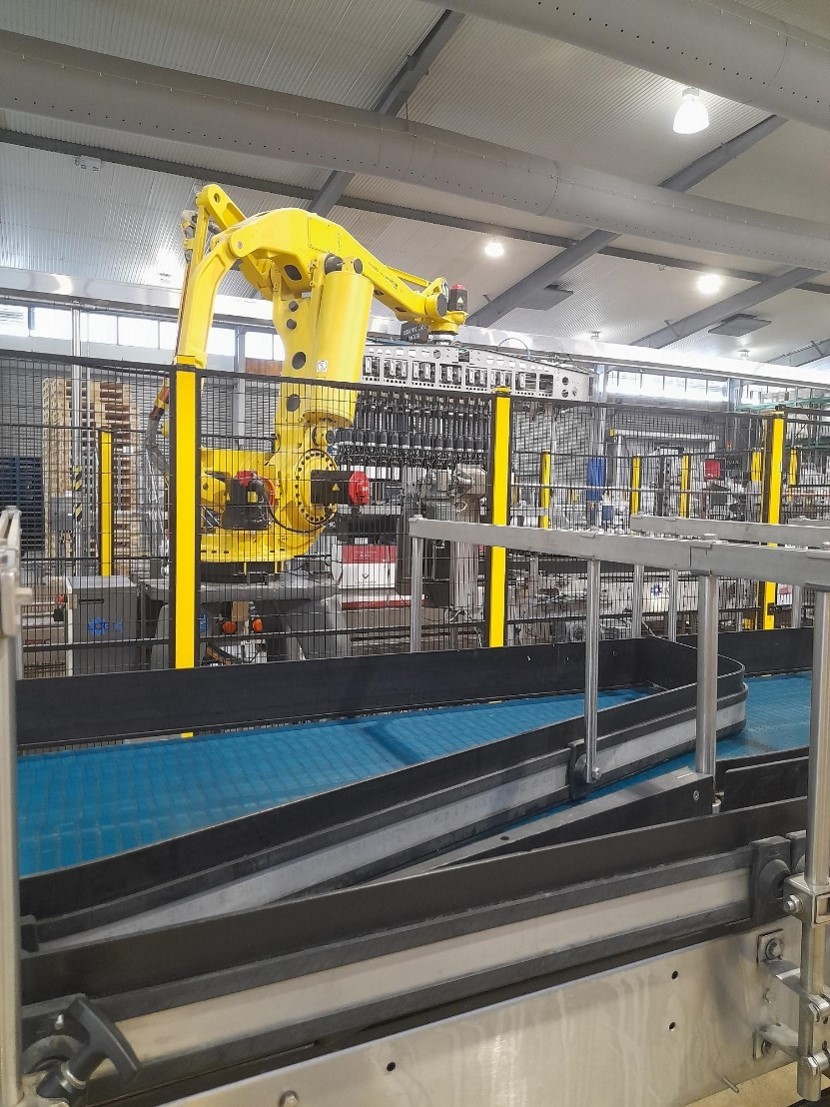

| 24 | 1x | Fanuc Robot packer | |

| 25 | 1x | Camera system IFM | |

| 26 | 1x | Ink jet printer | |

| 27 | 1x | Carton conveyors | |

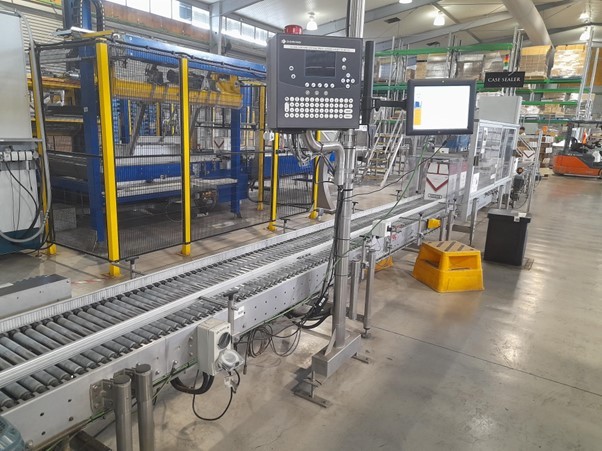

| 28 | 1x | Case sealer | |

| 29 | 1x | Carton conveyors | |

| 30 | 1x | Line divider | |

| 31 | 1x | Palletizer | |

| 32 | 1x | Auto Wrapping machine | |

| 33 | 1x | Pallet roller conveyor | |

| 34 | 1x | Manual wrapping | |

| 35 | 1x | Manual wrapping | |

| 36 | 1x | CIP | |

| 37 | 1x | Filtration skid | |

| 38 | 2x | De Labeller | |

| 39 | 1x | Screw cap elevator | |

| 40 | 1x | Pallet Wrapper |

Inventory items (id # & owner notes, included):

1.BOTTLE DEPALLETISER WITH DE-ELEVATOR

Make: CBS ENGINEERING LTD

Model: ABD4

Manufacture date: March 1998, New Zealand

Dimensions: L=9700mm, W=2000mm, H=3900mm

Speed: 12000b/h

Capability: Standard pallet (1200mm x 1000mm) and Australian pallet. Max height of the pallet 2000mm.

Major maintenance in

the last 5 years: Replaced all pneumatic cylinders, replaced all air lines (hoses and fittings),

replaced chains, sprockets and bearings, overhaul gearmotors,

replaced gearmotors of the De-elevator, replaced De-elevator sliders and griper chains,

replaced top table conveyor chains and wear strips, replaced pallet safety beam sensors,

replaced drives in electrical cabinet and did major safety improvement.

Removal instructions: Disassemble and use crane and forklift.

Operator Manual: Yes

Service provider: N/A

.....................................................................................................

2 DE-ELEVATOR

……………………………………………………………………………

3. INSPECTION CAMERA WITH REJECTING TABLE

Make: BANNER Engineering

Model: Smart Camera

Manufacture date: 2010

Capability: Inspects rim of the bottle.

Operations manual: No

Service provider: CSE-W.Arthur Fisher

………………………………………………………………………….

4. KRONES RINSER

Make: KRONES

Model: Variojet K563-760

Manufacture date: 2007, Germany

Dimensions: L=3000mm, W=3400mm, H=2500mm

Speed: 12500b/h

Capability: There are 48 rinsing heads and it can handle 19 different types of bottles

(750ml, 1L, 1.5L, 375ml and 187ml). The rinsing can easily be transformed to air or nitrogen.

Major maintenance in

the last 5 years: Machine has been serviced evry year according to the Krones recommendation.

Removal instruction: Use crane, for detailed instructions see Manual.

Operation manual: Yes (including “KRONES eCat” software CD for Spare Parts ordering)

Service provider: Krones NZ

……………………………………………………………………………..

5. KRONES FILLER

Make: KRONES

Model: Mecafil K123-821

Manufacture date: 2007, Germany

Dimensions: L=4100mm, W=3400mm, H=2500mm + Electronic Tower

Speed: 12500b/h or 208b/min

Capability: There are 54 filling heads, and it can fill 19 different types of bottles

(750ml, 1L, 1.5L, 375ml and 187ml). This is double pre-evacuation counterpressure filler.

Electronic Filler with pneumatic filling valves.

Major maintenance in

the last 5 year: Machine has been serviced every year according to the Krones recommendation.

All data are stored in MEX. We replaced main distributor and bottle plates (pedestals) cam in 2023.

Removal instructions: Use crane, for detailed instructions see Manual

Operations manual: Yes (including “KRONES eCat” software CD for Spare Parts ordering)

Service provider: Krones NZ

……………………………………………………………………………

6. SCREW CAPPER TECHNOVIN

Make: TECHNOVIN

Model: E VA/12

Manufacture date: 2002, Switzerland

Dimensions: L=2200mm, W=1500mm, H=2100mm + Cap Distributor (1000mm)

Speed: 12500b/h

Capability: Automatic Capper with 12 capping heads. It can cap 750ml, 375ml 1.5L Burgundy

and Bordeaux bottles with 30 x 60mm cap.

Major maintenance in

the last 5 years: Machine and capping heads have been serviced regularly on weekly, monthly, and yearly basis.

All data are stored in MEX. We replaced capping heads housings (bushes), cam, cam followers (bearings),

forks, spacer support pins and scrapers, replaced hopper cap elevator belt in 2023/24 major service.

Removal instructions: Use forklift

Operations manual: Yes (including Spare parts book with drawings)

Service provider: VINMAX Systems

…………………………………………………………………………

8. LASER CODER WITH DPX FUME EXTRACTION SYSTEM

Make: DOMINO

Model: D320i

Manufacture date: 2022, UK

Capability: Print date and tank number on the bottle

Operations Manual: Yes

Service provider: CODEMARK

…………………………………………………………………………

9. TAP-TONE

Make: TELEDYNE TAPTONE

Model: T550 APXD

Manufacture date: 2019, USA

Capability: Ultrasound cap seal (liner) inspector

Operations manual: Yes

Service provider: I.E.S Limited

………………………………………………………………………

10. KRONES CHECKMAT 1 WITH REJECTING TABLE

Make: KRONES

Model: CHECKMAT K707-BPD

Manufacture date: 2007, Germany

Capability: Bottle fill level inspector by using radioactive source with Rejector and Rejecting Table

Operations manual: Yes (including Radiation Safety requirements and radioactive source Licence

from NZ Ministry of Health Radiation Office)

Removal instructions: Use forklift.

Warning: You are dealing with closed radioactive source

Service provider: Krones NZ

……………………………………………………………………………

11. KRONES CHECKMAT 2 WITH REJECTOR

Make: KRONES

Model: CHECKMAT K731-958

Manufacture date: 2008, Germany

Capability: Cap quality inspector using double camera system and bottle level inspector using radioactive source

Major maintenance in

The last 5 years: Replaced faulty PCI-Framegrabber P5CTR Compact Card in 2023

Removal instructions: Use forklift.

Warning: You are dealing with closed radioactive source

Operations manual: Yes (including Radiation Safety requirements and radioactive source

Licence from NZ Ministry of Health Radiation Office)

Service provider: Krones NZ

……………………………………………………………………………

12. CONVEYORS (ACCUMULATION TABLE) 1

Make: CALMAC

Model: ACCUMULATION TABLE

Manufacture date: 2013, New Zealand

Dimensions: L=26000mm, W=400mm, H=1300mm (including CONVEYORS-ACCOMULATION TABLE 2)

Capability: Standard conveyors (6 sections with 4 chain lines) powered with 6 SEW-

EURODRIVE gearmotors and controlled by DANFOSS drives and ALLEN BRADLY PLC.

It can accumulate 800 bottles (750ml Burgundy bottle)

Major maintenance in

the last 5 years: Conveyors has been regularly serviced every year.

All maintenance data are stored in MEX. We replaced all conveyor chains in 2019.

Removal instructions: Disassemble it and use forklift.

Operations manual: No

Service provider: CALMAC CONVEYORS & TRANSMISSIONS

………………………………………………………………………………

13. CONVEYOR (ACCUMULATION TABLE) 2

…………………………………………………………………………………

14. BLOWER SONIC (EXTERNAL DRIER)

Make: SONIC AIR SYSTEM

Model: SONIC 150/150C

Manufacture date: 2010, USA

Dimensions: L=820mm, W=700mm, H=1520mm

Capability: Blowing water from bottles (drying bottles before label application)

Major maintenance in

The last 5 years: Machine has been serviced according to the manufacturer’s recommendation.

All data are kept in MEX. Replaced bearing cartridge in May 2023

Removal instructions: Disassemble and use forklift

Operations manual: Yes

Service provider: SPLATT ENGINEERING NZ LTD

……………………………………………………………………………

15. DEHUMIDIFIER

Make:

……………………………………………………………………………

17. LABEL INSPECTION CAMERA SYSTEM

Make: KANDO INNOVATION

Model: SYSTEM WITH 4 CAMERAS

Manufacture date: 2013, New Zealand

Dimensions : L=1600mm, W=1100mm, H=1550

Capability: The system detects correct position of front and back label,

spacing between front and back label, correct height of the labels,

correct market, damaged and missing label

Major maintenance in

the last 5 years: Replaced power supply and hard drive in 2018. Replaced faulty camera No0,

power supply and touch screen in Feb 2024.

Major maintenance

needs to be done: N/A

Removal instructions:

Operations Manual: Yes

Service provider: KANDO Innovation

………………………………………………………………………………

18. CONVEYORS – ROBOT PACKER IN FEED

Make: SIPAC

Model: 010-011

Manufacture date: 2013, Italy

Dimensions: L=21000mm, W=700mm, H=1300mm

Capability: 4 chain lines accumulation conveyor which supply Robot Packer with bottles.

It is powered with 5 SEW-EURODRIVE gearmotors and controlled by DANFOSS drives

and SIMENS PLC included in Robot Packer Touch Screen.

The label inspection Camera System rejecting table is part of the conveyor.

Major maintenance in

the last 5 years: Conveyors has been regularly serviced every year.

All maintenance data are stored in MEX. We replaced all conveyor chains in 2019.

Removal instructions: Disassemble it and use forklift.

Operations manual: Yes

Service provider: COSTA ENTERPRISES

CONVEYOR & TRASMISSION

…………………………………………………………………………………

19. MANUAL PACKING TABLE

Make: CALMAC ENGINEERING LTD

Manufacture date: 2003, New Zealand

Dimensions: L=4600mm, W=2300mm, H=1300mm

Capability: Two lines manual packing table

Removal instructions: Use forklift

Operations manual: No

………………………………………………………………………………….

20. TAPE MACHINE x 2

Make: SALLOTAPE PRODUCTS (NZ) LTD

Model: SIAT

Manufacture date: 2003, New Zealand

Dimensions : L=1800mm, W=700mm, H=1500mm

Capability: Tape carton sealer used on manual packing line to seal 12 packs and 6 packs cartons

Major maintenance in

the last 5 years: Machines have been regularly serviced every 12 months.

Removal instructions: Use forklift

Operations manual: Yes

Service provider: TOTAL SOLUTIONS

…………………………………………………………………………………..

21. CASE ERECTOR WITH PRINTING DEVICE x 2

Make: BORTOLINKEMO

Model: FC35

Manufacture date: 2013

Dimensions: Case Erector L=30mm, W=1400mm, H=2353mm

Printing Device L=3000mm, W=1450mm, H=2353mm

Speed: 1500 C/H – 6 packs case

Capability: Automatic Case Erector with Printing Device.

Tolerable dimensions of the cases that can be loaded into the machine: 295 x 240 min, 780 x 750 max.

We used it to make 6 and 12 packs cases of 750ml and 375ml Burgundy and Bordeaux bottles.

Major maintenance in

the last 5 years Machine has been regularly serviced and maintained according

to the manufacture’s recommendation. All data are stored in MEX.

The last big overhaul has been done in 2020.

We also upgraded (improved) Height Adjustment System in 2023.

Removal instructions: Complete machine weight is 1000Kg. Separate Case Erector from Printing Device and use forklift.

Operations manual: Yes (including spare parts book)

Service provider: COSTA ENTERPRISES NORDSON

………………………………………………………………………………

22. CASE PRINTING DEVICE x2

Make: BORTOLINKEMO

Model: ACS09

Manufacture date: 2013, Italy

Dimensions: L=3000mm, W=1450mm, H=2353mm

Speed: 1500 C/H

Capability: It is part of the Carton Erector and we use it to feed Carton Erector with cartons.

It has been designed to make print for generic cartons. However,

we made printers redundant and disassembled them.

Major maintenance in

The last 5 years: Disconnected and took off 8 ink jet printer heads (4 on each machine).

Replaced pneumatic cylinder, pneumatic fittings, and carton feeder chains in 2018.

Removal instructions: Disassemble and use forklift.

Operations manual: Yes (including Spare Parts book)

Service provider: COSTA ENTERPRISES

…………………………………………………………………………………

23. SIPAC CARTON CONVEYORS

Make: SIPAC

Model: 010-011

Manufacture date: 2013, Italy

Dimensions: L=50000mm, W=600mm, H600=mm

Capability:SIPAC complex conveyor system which supply cartons to Robot Packer,

Carton Sealer and Palletiser. The system consists of chain conveyors, roller conveyors and belt conveyors.

It is powered with 14 SEW-EURODRIVE gearmotors and controlled by

10 DANFOSS VLT Decentral drives and SIMENS PLC included in Robot Packer

and Palletiser Touch Screens.

Major maintenance in

the last 5 years: Conveyors has been regularly serviced every year.

All maintenance data are stored in MEX. We replaced all conveyor chains in 2023,

conveyor belts in 2022 and we replaced roller conveyors driving belts in 2021.

Removal instructions: Disassemble it and use forklift.

Operations manual: Yes (including Spare Parts book)

Service provider: COSTA ENTERPRISES CONVEYOR & TRASMISSION

…………………………………………………………………………………

24. FANUC ROBOT PACKER (HERON CARTONING MACHINE)

Make: LOGIK TECHNOLOGY

Model: HERON SN C11562

Manufacture date: 2013, Italy

Dimensions: L=10500mm, W=3700mm, H=3500mm

Speed: 18000b/h

Capability: Robot head can pick up 48 bottles at the time and place it in 6 or 12 packs cartons.

It has 17 formats for different type of the bottles (750ml and 375ml Burgundy,

TD Burgundy, Bordeaux, Premium Bordeaux and Sparkling bottle)

and different size of the cartons. Machine is fully automatic

and it is controlled by SIMENS PLC and touch screen

Maintenance in the last 5 years: Machine has been regularly serviced as per manufacturers recommendation

and it is in excellent condition.

All maintenance records are stored in MEX.

The Robot head overhaul is done in May 2022 (we do it every 3 years).

We replaced gearbox of the Fanuc robot joint J2 in April 2022.

Minor service (6 monthly joints greasing) has been done in February 2024.

Operations manual: Yes (including Fanuc service manual and spare parts book)

Service provider: COSTA ENTERPRISES FANUC OCEANIA PTY LIMITED

…………………………………………………………………………………

25. IFM CAMERA SYSTEM

Make: IFM

Model: EFECTOR PMD 3D

Manufacture date: 2015, New Zealand

Capability: This Camera System consists of 2 cameras and Touch Screen

and inspects correct number of bottles in the box and quality of the sealed box.

Operations manual: Yes (CD Operating Software E3D200 Version 1.1)

Service provider: IFM

………………………………………………………………………………

26. INK JET PRINTER

Make: DOMINO

Model: Ax350i

Manufacture date: 2018, UK

Capability: Ink jet printer with touch screen. We used to print wine details on the cartons.

It is in an excellent condition.

Operations manual: Yes (CD)

Service provider: CODEMARK

………………………………………………………………………………

27. SIPAC CARTON CONVEYORS

…………………………………………………………………………………

28. CASE SEALER

Make: BORTOLINKEMO

Model: MARA HM

Manufacture date: 2013, Italy

Dimensions: L=4100, W=800mm, H=2500mm

Speed: 3000c/h – 6 packs case

Capability: Machine can seal cartons with following dimensions:

Min 200mm x 150mm x 130mm

Max 500mm x 400mm x 400mm

Major maintenance in The last 5 years: Machine has been regularly serviced as per manufacturers recommendation

and it is in excellent condition.

All maintenance records are stored in MEX. In the last 3 years we replaced all three gearmotors,

bottom and top belts, pneumatic cylinders, glue machine modules (4), 2 drives and all relays.

Removal instructions:Disassemble and use the forklift

Service provider: COSTA ENTERPRISES

NORDSON

…………………………………………………………………………………

29. SIPAC CARTON CONVEYORS

…………………………………………………………………………………….

30. LINE DIVIDER

Make: LINE PACK

Model: D27.F370/1-2F

Manufacture date: 2013, Italy.

Dimensions: L=4000mm, W=1700mm, H=1500mm

Capability: The machine is in feed and integral part of Palletiser. It divide cartons left/right

and it can handle 3000b/h 6 packs cartons.

Major maintenance in

the last 5 years: Machine has been regularly serviced as per manufacturers recommendation

and it is in an excellent condition. All maintenance records are stored in MEX.

Major overhaul has been done in 2022.

Removal instructions: Separate machine from Palletiser and use forklift.

Operations manual: Yes (include spare parts book)

Service provider: COSTA ENTERPRISE

…………………………………………………………………………………

31. PALLETISER

Make: LOGIK TECHNOLOGY

Model: WOLF PALLETISER, SN C11561

Manufacture date: 2013, Italy.

Dimensions: L=9200mm, W=10100mm, H=4200mm

Speed: 20 Pallets/h (28 cartons/layer x 5 layers)

Capability: Fully automatic palletiser with Spider. Spider supply pallets, slip sheets and layer boards.

Major maintenance in

the last 5 years: Machine has been regularly serviced as per manufacturers recommendation

and it is in excellent condition. All maintenance records are stored in MEX.

In the last 5 years we replaced main head motor with break in 2019,

overhaul Spider (replaced sliding bearings, pneumatic cylinders pneumatic lines and fittings,

toothed belts, suction cups and clamps), serviced Spider’s motors and gear boxes, serviced pallet roller conveyors

(new bearings and chains), replaced pusher’s sprockets and toothed belts in 2022.

Removal instructions: Disassemble machine and use crane and forklift.

Operations manual: Yes (include spare parts book)

Service provider: COSTA ENTERPRISES

………………………………………………………………………………

32. AUTOMATIC WRAPPING MACHINE

Make: J.M.P. ENGINEERING LTD

Model: PALLET WRAPPING SYSTEM

Manufacture date: 2010, New Zealand

Speed: 20 Pallets/h (28 cartons/layer x 5 layers)

Capability: Automatic wrapping machine with turn table controlled with PLC and little Touch Screen.

This system can receive loaded pallets in a production line and wrapping them with a clear plastic stretch wrap.

Major maintenance in

The last 5 years: Machine has been serviced every year.

All maintenance data stored in MEX. We replaced main bearing and rollers of the turn table

, replaced all pneumatic cylinders and fittings, replaced UP/DOWN motor in 2022.

Removal instructions: Disassemble and use forklift.

Operations manual: Yes

Service provider: J.M.P. ENGINERING LTD

…………………………………………………………………………

33. SIPAC PALLET ROLLER CONVEYOR

………………………………………………………………………..

34. MANUAL WRAPPING MACHINE

………………………………………………………………………….

35. MANUAL WRAPPING MACHINE

………………………………………………………………………

36. CIP kitchen skid – 4 tanks: hot water, caustic, citric, recirculation tanks

- on board CIP pumps & control panel.

………………………………………………………………………

37. Final FILTRATION skid & pump:

- 3 filtration trains: 2x12x10inch, 2x3x30inch, 2x3x30inch

- Lobe feed pump.

…………………………………………………………………………

38. De-labeller x 2

…………………………………………………………………………

39. Belt elevator

……………………………………………………………………………

40. JMP Pallet wrapper

………………………………………………………………………………