No. 1392 Beer Bottling 3000bph NZ

Beer Bottling/Glass Filler 3000bph New Zeland

Owners have moved 100% to canning.

Glass filler is surplus to requirement,

2017 European built bottle rinser/filler/crowner at up to 3000bph

Double pre-evacuation, very low dissolved oxygen.

Engineer is available to discuss technical and service history, manual and spares.

Industrial Brokers Ltd (exclusive sales agent )

- Ed O’Donnell

- 0274 442 944

- +64 (0) 274 442 944

- ed@ibl.co.nz

Terms and Conditions

- The plant and equipment is offered on a "second-hand" & “as is where is” basis.

- No warranties or guarantees are offered.

- All sales are by negotiation.

- Sale and Purchase Agreement applies.

- Technical data, service history & drawings only where available.

- Site visit PPE requirements apply.

- Inspections by appointment only. Call 0274 442 944

Inventory

| Moravek 12/12/1 rinser / filler/ crowner - Tribloc 2017 |

| 330ml bottle change parts |

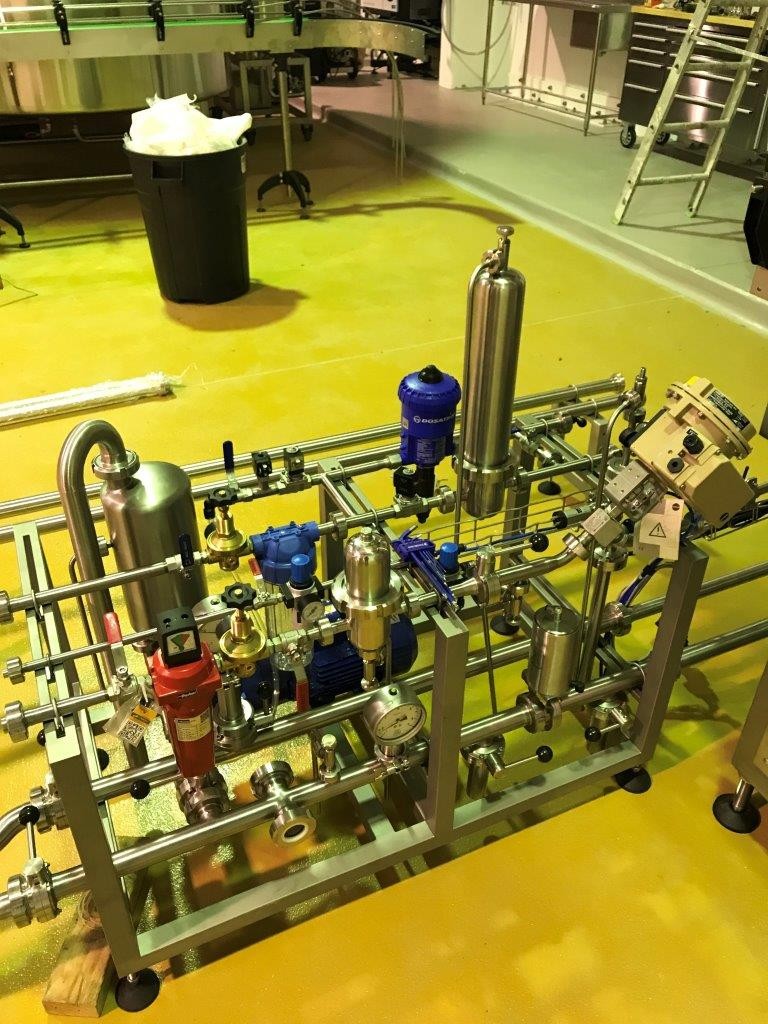

| Pre filler valve cluster including vaccuum pump, CIP return line and sample valve |

| Two stage rinser - sterile water filter & Dosatronic peracetic doser |

| Incoming CO2 gas sterilisation |

| 500ml bottle change parts |

| CIP cups |

https://dzwpl.bpmsafelink.com/c/pxmDWwqwPUSIT2TcESkzXQ

2nd pic is the external valve cluster, including:

Vacuum pump with pressure gauge

Peracetic acid / sanitiser automatic doser (2 stage pre-rinse on the filler: water rinse then sanitise)

2 x CO2 filters

2 x water filters

Compressed air inlet and pressure gauge

Incoming product sight glass, pressure gauge, sample valve and pneumatic ball valve for entry to filler

Automatic pressure relief valve for controlled relief of CO2 head pressure in filler bowl to maintain required beer level

CIP return pipe and butterfly valve