×

Home

Show All

No. 1486 2 x 5000ltr stainless tanks

No. 1485 6 x 1200ltr stainless tanks Wellington

No. 1484 1200ltr Brewery Wellington SOLD

No. 1482 Winery Plant & Equipment Invivo Wines NZ SOLD

No. 1481 Barrel Racks x 600 Blenheim NZ

No. 1478 Unique Opportunity - Vinoptima Gisborne Winery NZ SOLD

No. 1474 Distilling Plant NZ New Unused

No. 1472 Cross-Flow Filter

No. 1471 Boiler 500kw

No. 1470 Heat Exchanger "Dimple Flo"

No. 1469 Stainless Tanks and Equipment Auckland

No. 1467 Brewery Plant 1200ltr NZ SOLD

No. 1461 Brewery 300ltr Victoria

No. 1455 Seismic Barrel Racks x 200 HB

No. 1454 Diesel Boiler Cromwell

No. 1453 Press Diemme T26 Velvet series New Unused Blenheim

No. 1452 Wine Tanks 1 x 10kltr 1 x 20kltr Nelson

No. 1451 Kegs, Small tanks & Bins

No. 1442 Villa Maria / Indevin Bottling & Packaging Assets A

No. 1422 6 x 6000ltr Stainless Tanks Blenheim

No. 1417 New Micro Brewery, & Distilling Equipment NZ

No. 1413 Villa Maria/Indevin Wine Tanks Auckland 2.3mil Ltrs SOL

No. 1409 Labeller Wine Bottles 750 & 375ml

No. 1407 4 x 12,000ltr ss wine tanks

No. 1392 Beer Bottling 3000bph NZ

No. 1386 Indevin Winery Plant & Equipment Rare Opportunity

No. 1365 DE Filter 10 sq mtr Melbourne

No. 1348 Meheen 6head Filler Tas AU

No. 1346 Meheen Filler 6head NSW

No. 1248 Meheen 6 head Fillers Christchurch

No. 1483 Winery Plant Waikato SOLD

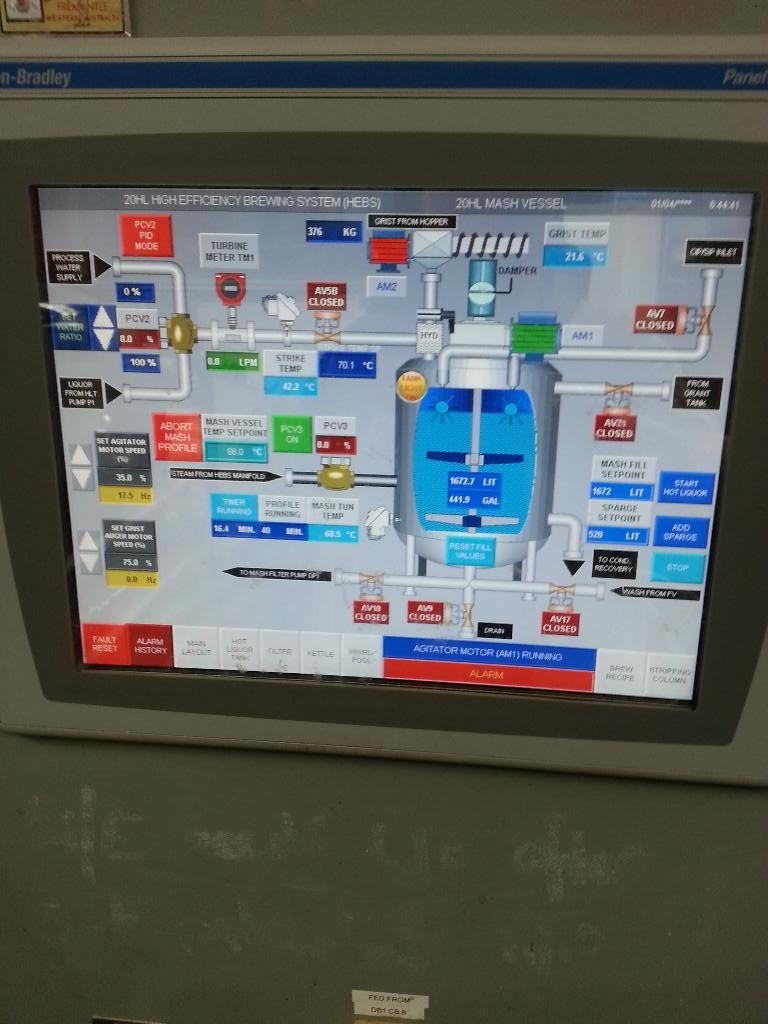

No. 1209 20hl Brewhouse Sydney

Sorry, this is no longer available, please select from the list provided.

Sorry, this is no longer available, please select from the list provided.