No. 1291 Bottling Line 2018 Sydney

×

Home

No. 1432 6 x 50,000ltr Wine Tanks Auckland

No. 1431 6 x 54,000ltr Wine Tanks Auckland

No. 1430 Distillery Boiler & Tanks, South Island NZ

No. 1427 Small Wine Tanks Auckland

No. 1426 8 x 50,000ltr Wine Tanks AK SOLD

No. 1425 Wine Tanks & Equipment AK

No. 1424 Petrochemical Tanks, Northland SOLD

No. 1423 Wine Tanks 10 x 25,000Ltr Auckland SOLD

No. 1422 6 x 6000ltr Stainless Tanks Blenheim

No. 1420 Wine Tanks 5 x 15,000ltr

No. 1419 20 head Wine Bottling Line Auckland

No. 1418 140,000ltr Wine Tank

No. 1414 Catwalks & Stairs All SOLD

No. 1413 Wine Tanks Auckland 2.3mil Ltrs

No. 1411 Power Distribution

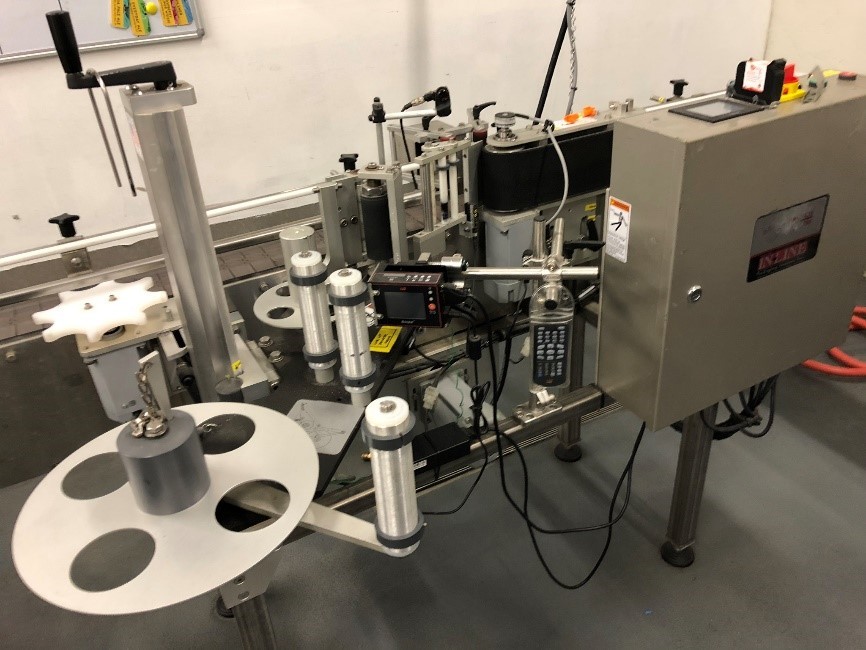

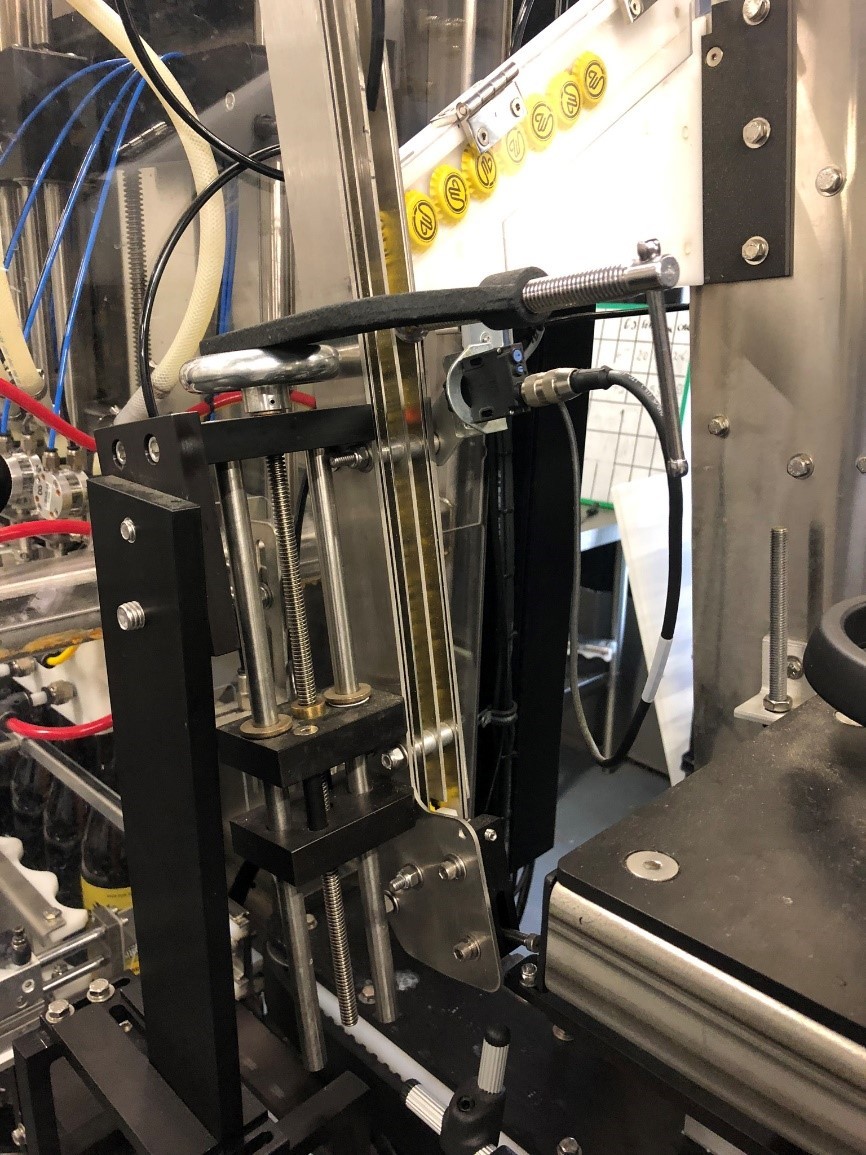

No. 1409 Labeller Wine Bottles 750 & 375ml

No. 1407 4 x 12,000ltr ss wine tanks

No. 1405 Brewhouse 10hl new/unused Sydney

No. 1403 Wine Tanks 2 x 40,000ltr 12 x 25,890ltr

No. 1401 Framax Filler NSW

No. 1392 Beer Bottling 3000bph NZ

No. 1390 Case Over Packer Hawkes Bay NZ

No. 1386 Winery Plant & Equipment Rare Opportunity NZ

No. 1371 500ltr Micro brewery Turnkey Qld

No. 1366 ISO transport tank, 24,000ltr, 4bar, Melbourne SOLD

No. 1365 DE Filter 10 sq mtr Melbourne

No. 1362 Winery plant and equipment Hawkes Bay

No. 1357 Wine tanks 108kltr , 54kltr

No. 1348 Meheen 6head Filler Tas AU

No. 1346 Meheen Filler 6head NSW

No. 1339 Labelling machine and Receival bin

No. 1322 Bottling Line Melbourne 330ml & 650ml

No. 1248 Meheen 6 head Fillers Christchurch

Sorry, this alert is no longer available, please select an alert from the list provided.